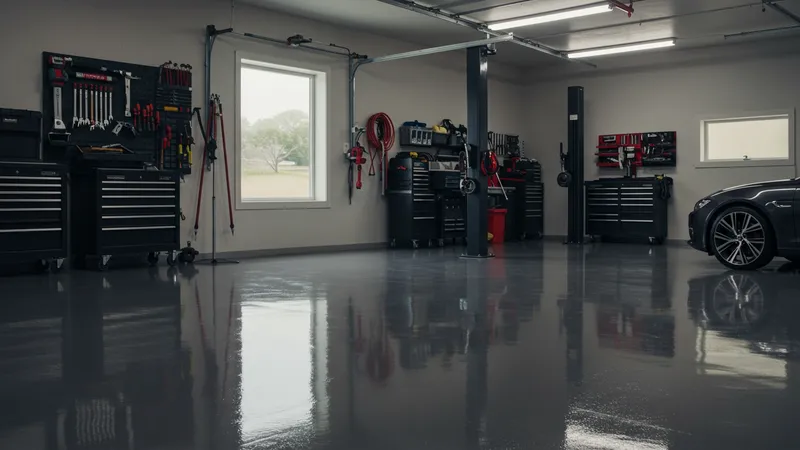

Walking into a garage, most people notice the floor less than the tools or vehicles it holds. Yet, those who have upgraded with a specialty coating understand that transforming this underfoot surface isn’t just about aesthetics—it’s about durability, hygiene, and even property value. A comprehensive understanding of garage floor coatings reveals how selecting the right type can radically improve the daily usability and long-term resilience of this space, especially in demanding climates and high-traffic environments typical in the United States.

Garage floor coatings are engineered finishes applied to concrete surfaces to protect against stains, abrasions, chemicals, and moisture. These products go far beyond basic paint, offering tailored levels of gloss, slip-resistance, and thickness. The selection process involves not just picking a finish but weighing performance, aesthetics, maintenance requirements, and cost, making it crucial to explore every detail before making a choice.

One of the most prominent trends in the United States is the shift from plain concrete floors to highly engineered coating systems that can withstand not just parked cars, but also heavy workshop tools, garden equipment, and even harsh deicing chemicals tracked in during snowy winters. Epoxy-based solutions like Rust-Oleum’s kits are easy to install and maintain, making them a top pick among DIY enthusiasts and budget-focused homeowners alike.

Products like Quikrete’s Epoxy Garage Floor Coating offer an accessible entry-point for those tackling their first floors, providing both the strength needed to handle daily wear and a fast-curing formula that minimizes downtime. While the cost remains reasonably low, even basic epoxy options can create a more polished, easy-to-clean environment compared to bare concrete.

For those seeking professional-grade durability and a custom look, kits like Armor Clad feature multi-step, multi-layer finishes often chosen for garages that double as showrooms or workshops. These advanced coatings integrate color flakes for style and extra grip, while extending floor life well beyond what a simple paint can offer. With a higher upfront cost, they’re especially popular in upscale suburban and rural properties across the US.

The range of garage floor coatings—from affordable, user-friendly systems to high-end industrial-grade solutions—means there is an option for every home and budget. But just how does performance truly compare across these options? The deeper details reveal even more valuable insights ahead...

Understanding the core differences between epoxy, polyurea, and acrylic garage floor coatings is crucial for any informed decision. Epoxy remains the most widely used, thanks to its balanced blend of cost, strength, and chemical resistance. Polyurea, often selected in commercial settings, boasts rapid curing and exceptional flexibility for climates with temperature swings. Acrylic solutions, while fast to apply, typically fall short in longevity compared to their epoxy or polyurea counterparts, but may appeal to those looking for a quick refresh.

Rust-Oleum EpoxyShield is a classic example of a solvent-based epoxy that balances ease of use and performance. With a glossy finish and moderate chemical resistance, it handles oil, brake fluid, and cleaning agents well—common hazards in U.S. garages. For households where DIY installation is a necessity, its clear, straightforward instructions reduce the risk of common mistakes like uneven coverage or premature peeling.

On the other hand, premium kits like Armor Clad rely on two-part epoxy or polyurea blends, reinforcing the surface with tough, interlocking polymers. This results in a denser, more damage-resistant floor that stands up to dropped tools and rolling equipment. The additional topcoat, included in higher-end kits, further enhances stain and UV resistance—an advantage for garages with direct sunlight or exposed driveways.

The application process can greatly differ among these options. Budget-friendly coatings such as Quikrete require careful surface prep and a 24- to 48-hour cure time, while advanced polyurea systems might return a garage to full use in a single day. The divergence in drying times, environmental tolerances, and application complexity all play major roles in the selection process, impacting not just convenience but the ultimate longevity of the coated floor.

Cost is frequently the deciding factor for many homeowners in the United States considering garage floor coatings. EpoxyShield and similar DIY kits generally run between $120–$150 for a 2-car garage, with costs influenced by square footage, prep products, and optional upgrades such as color chips. Quikrete offers an even lower initial spend, although additional topcoats for superior gloss or durability may add to the budget.

Labor costs in the US, if a professional is hired, can surpass product expenses. Installation often ranges from $2 to $6 per square foot, with intricate designs or advanced materials like Armor Clad tipping the scale higher. In total, professionally finished floors using commercial-grade products may reach $1,500–$4,000 for an average 2-car garage, reflecting the skill and specialty tools required.

Long-term maintenance and potential repairs should be factored into the cost equation. Epoxy finishes, for instance, tend to require recoating every 3-5 years in high-use areas, whereas thicker or professionally installed polyurea floors can last a decade or more before any refresh is needed. The initial investment may be higher, but reduced upkeep can justify the cost for those planning to stay in their home long-term.

Product warranties also play into overall value. Rust-Oleum, Quikrete, and Armor Clad each offer various guarantees on adhesion, gloss retention, and wear resistance, with more premium kits often providing extensive coverage. In the United States, warranty claims tend to be straightforward, especially when installation directions are carefully followed—a consideration that underscores the importance of proper surface preparation and application technique.

The advantages of coating a garage floor go well beyond a clean, attractive appearance. For many U.S. homeowners, the primary benefit is improved resistance against common automotive fluids and household chemicals, which can quickly stain or degrade untreated concrete. EpoxyShield and similar coatings create a sealed surface, making spills easy to clean and reducing the risk of embedded odors or permanent blemishes.

Another significant benefit—often overlooked—is increased safety and light reflection. Decorative flakes found in Armor Clad kits add texture, reducing the risk of slipping when the floor is wet. Meanwhile, the enhanced gloss finish can brighten a garage’s appearance by reflecting more natural and artificial light. This effect is prized in workspaces, making dropped screws easier to spot and detailed projects less straining on the eyes.

Garage floor coatings also help control dust, a common nuisance with bare concrete. By trapping loose particles and resisting abrasion, coated floors require less sweeping and reduce the spread of dust to adjacent living spaces. In the U.S., where attached garages often serve as secondary storage or utility rooms, this feature is especially useful in keeping the entire home cleaner.

Finally, enhanced curb appeal and property value provide indirect returns on investment. A well-coated garage suggests overall pride of ownership, which is attractive to prospective home buyers. Real estate professionals note that garages with professionally finished floors tend to photograph better for listings and leave a positive impression during inspections, supporting higher resale prices and faster sales in competitive markets.

Selecting the most suitable garage floor coating in the United States hinges on several variables. The climate, the garage’s primary use, initial budget, and willingness to tackle a DIY project all inform the decision. For example, EpoxyShield’s accessibility and user guidance make it a favorite for first-time users, while Armor Clad suits those willing to invest time and expense for a long-lasting, high-end finish.

Evaluating foot and vehicle traffic is essential. Garages that serve as primary entry points or double as workshops demand thicker, more robust coatings, favoring multi-layer epoxy or polyurea blends over single-step acrylics. Quikrete’s affordability may suit renters or those with lighter usage, but lifelong homeowners often see value in stepping up to premium options with longer warranties and layered protection.

Proper surface preparation remains the cornerstone of successful application regardless of the product chosen. Cleaning, repairing cracks, and etching the concrete ensures maximum adhesion—a step frequently cited in user reviews and industry guidance across the U.S. Rushing or skipping prep work is a leading cause of poor results, including peeling, bubbling, or premature wear.

Ultimately, the best garage floor coating is the one that aligns with both functional requirements and lifestyle preferences. The balance between installation ease, durability, cost, and customization ensures there is a solution for every American home. Understanding these nuanced details equips you to make a confident, informed choice, unlocking the full value and versatility of your garage floor.